You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printing - why haven't you jumped in yet?

- Thread starter Hotspurr

- Start date

JCK75

Member

Oh wow, yea 3D printing is my main hobby outside of gaming..

My first printer was a Monoprice Mini, but I returned it after having tons of issues (later learned that my profiles meant to reduce stringing were the actual issue causing clogs, if you retract too far hot filament into a cold PTFE tube connector results in clogs)

So I then got an Anet A8 for $150, and I never really got it quite right TBH, it's a helluva deal but takes a ton of work to make it great.

So then I moved on to a Prusa i3 MK2S Kit and I love that printer, still is my primary

I retired my Anet and replaced it with a Creality Ender 3, the Ender is the one I'd suggest to all my friends being the print quality equals my Prusa but at a pricetag of under $250 (my Prusa took me an entire day to put together, the Ender 3 took me 30 minutes).

My last major print

My first printer was a Monoprice Mini, but I returned it after having tons of issues (later learned that my profiles meant to reduce stringing were the actual issue causing clogs, if you retract too far hot filament into a cold PTFE tube connector results in clogs)

So I then got an Anet A8 for $150, and I never really got it quite right TBH, it's a helluva deal but takes a ton of work to make it great.

So then I moved on to a Prusa i3 MK2S Kit and I love that printer, still is my primary

I retired my Anet and replaced it with a Creality Ender 3, the Ender is the one I'd suggest to all my friends being the print quality equals my Prusa but at a pricetag of under $250 (my Prusa took me an entire day to put together, the Ender 3 took me 30 minutes).

My last major print

JCK75

Member

How durable is the plastic? I would make a phone stand for my car if its decently durable

Like the other guy said PLA is the most common, it's way more durable than you think it would be so long as you provide enough infill, PLA is made to be biodegradable so it will break down in direct sunlight over time, ABS is toxic AF but is much more durable.. But so long as you get a good printer that can do many materials you have options that have the non picky print features of PLA while being as durable as ABS (PETG is the go to for me right now when I need something that will last, it prints with no fuss and is strong AF)

Iaterain

Member

I love 3d printing technology and I was thinking about buying one but I have no experience in 3d modelling and no friends with 3d printers around.

I have drawing/painting skills and I was willing to start learning 3d modelling, but it would be pricey experience if you just learning modelling and printing regularly.

If I had guarantees that I would be able to create and sell things it would be a great new hobby, but I'm afraid it would end up like an expensive toy in a wrong hands.

I have drawing/painting skills and I was willing to start learning 3d modelling, but it would be pricey experience if you just learning modelling and printing regularly.

If I had guarantees that I would be able to create and sell things it would be a great new hobby, but I'm afraid it would end up like an expensive toy in a wrong hands.

Codes 208

Member

Im more of a 2d artist. Im also a poor peseant with only a surface pro 4 (which is likely not gpu/cpu capable of 3d modeling)

I also cant make 3d models to save my life. Too complicated. Ive used a 3d model software before, but mainly to edit a mod in sims and it took hours just to color a pre-existing model. (This was back when i still had my gtx970)

I also cant make 3d models to save my life. Too complicated. Ive used a 3d model software before, but mainly to edit a mod in sims and it took hours just to color a pre-existing model. (This was back when i still had my gtx970)

Last edited:

JCK75

Member

I love 3d printing technology and I was thinking about buying one but I have no experience in 3d modelling and no friends with 3d printers around.

I have drawing/painting skills and I was willing to start learning 3d modelling, but it would be pricey experience if you just learning modelling and printing regularly.

If I had guarantees that I would be able to create and sell things it would be a great new hobby, but I'm afraid it would end up like an expensive toy in a wrong hands.

I'm a very big user of Blender, it's rough around the edges but 2.8 is coming which has major financial backing to make it an experience on par with the highly priced products, Once you get the basics down it's pretty easy.. the difficulty in 3D comes with retopology and materials and such, modeling and sculpting can be quite easy with some basic knowledge, and that's all you need for 3D printing as you want a high poly object, whereas animation/games need low poly with faked detail.

That should show you all you need to know to start making stuff and the cost is nothing at all since it's freeware.

2.8 is in beta still but it's a drastic transformation that gives it's UI a modern feel.. so I'd start with 2.79B until it's official

www.blender.org

It depends on what plastic you print with.

PLA is strong/stiff but a bit brittle and not very heat resistant.

ABS/ASA is also strong but softer compared to PLA, it is heat resistant though and UV resistant as well. ASA is what I use for my phone stand in my car.

Good to know thanks guys.Like the other guy said PLA is the most common, it's way more durable than you think it would be so long as you provide enough infill, PLA is made to be biodegradable so it will break down in direct sunlight over time, ABS is toxic AF but is much more durable.. But so long as you get a good printer that can do many materials you have options that have the non picky print features of PLA while being as durable as ABS (PETG is the go to for me right now when I need something that will last, it prints with no fuss and is strong AF)

How bad is PLA in heat? Does it melt and deform? And is ABS toxic to touch or just during printing?

Oh wow, yea 3D printing is my main hobby outside of gaming..

My first printer was a Monoprice Mini, but I returned it after having tons of issues (later learned that my profiles meant to reduce stringing were the actual issue causing clogs, if you retract too far hot filament into a cold PTFE tube connector results in clogs)

So I then got an Anet A8 for $150, and I never really got it quite right TBH, it's a helluva deal but takes a ton of work to make it great.

So then I moved on to a Prusa i3 MK2S Kit and I love that printer, still is my primary

I retired my Anet and replaced it with a Creality Ender 3, the Ender is the one I'd suggest to all my friends being the print quality equals my Prusa but at a pricetag of under $250 (my Prusa took me an entire day to put together, the Ender 3 took me 30 minutes).

My last major print

This looks spectacular. Nice finishing job!

JCK75

Member

Good to know thanks guys.

How bad is PLA in heat? Does it melt and deform? And is ABS toxic to touch or just during printing?

I use PLA on 99% of my prints, it's perfectly fine just if it sits in direct sunlight all day every day it will break down by design (biodegradable)

ABS only the fumes are bad, it's a Pain to print as the conditions have to be just right and it has to be enclosed (not for fumes but for print temperatures), I only use it when I want the final print to be unpainted, then you can smooth it with acetone vapors and it looks polished and beautiful) it may be a stretch to call ABS "Toxic" it's just not good to breathe the fumes.

I use PETG for prints I'm going to use in like the car as it has the lasting power of ABS but prints easily.

I use PLA on 99% of my prints, it's perfectly fine just if it sits in direct sunlight all day every day it will break down by design (biodegradable)

ABS only the fumes are bad, it's a Pain to print as the conditions have to be just right and it has to be enclosed (not for fumes but for print temperatures), I only use it when I want the final print to be unpainted, then you can smooth it with acetone vapors and it looks polished and beautiful) it may be a stretch to call ABS "Toxic" it's just not good to breathe the fumes.

I use PETG for prints I'm going to use in like the car as it has the lasting power of ABS but prints easily.

Is PETG better than PLA overall for quality or does PLA still have its own advantages.

Also do you mind sharing your finishing routines, eg. Sandpaper grits, primers, putty, paints, topcoat (and product brands)?

Ecto311

Member

I printed this and stuck magnet tape to the bottom so they don't move on this metal plate. The plate was supposed to look like metal and stone but the fuckin stone paint just looks dumb to me. My dad liked it as a gift and it's hanging in their living room right now. It was printed on my maker select with hatchbox wood filament. Since getting some UV filament my fuckin printer will just stop extruding at random. Makes it a real chore to dedicate any time to it since 1 out of 3 prints or so actually finishes. Did a ton of mods to the printer and it prints great but I can't find the time to find out why they just fail. I can do the same print 10 times with exact same settings and only a few times out of that will work. The faceook 3d printing group has a ton of posts about them doing the same so I wonder if it's the filament fuckin up with season changes or humidity.

TheShadowLord

Member

Is the FlashForge Finder 3D Printer the best affordable 3d printer?

Ecto311

Member

Is the FlashForge Finder 3D Printer the best affordable 3d printer?

Personally I would look at the CR-10 or Maker select. Those have bigger build volumes and I think the CR-10 is open but the maker select for the most part is open source and there are tons of resources for it. It does do better with some mods but out of the box it runs well and I think it's around $50 cheaper than the flash forge finder.

TheShadowLord

Member

cr 10 was like close to $500 on gearbest.Personally I would look at the CR-10 or Maker select. Those have bigger build volumes and I think the CR-10 is open but the maker select for the most part is open source and there are tons of resources for it. It does do better with some mods but out of the box it runs well and I think it's around $50 cheaper than the flash forge finder.

edit: and I assume you mean the monoprice maker select, right? Is it began enough to make a dead space marker?

Last edited:

Ecto311

Member

cr 10 was like close to $500 on gearbest.

edit: and I assume you mean the monoprice maker select, right? Is it began enough to make a dead space marker?

https://www.amazon.com/dp/B07DGV2L8Z/?tag=neogaf0e-20

Similar to the maker select. I mentioned the CR-10 just because of that type of printer and what it offers. The enclosed small print area ones seem really limited to me but depending on what you want to print like ABS a closed off printer might be better for you. Granted i have been fighting my maker select in the last few months I still like the machine and if I had the time I would rebuild the hot end to get rid of the issues I am having.

JCK75

Member

Is PETG better than PLA overall for quality or does PLA still have its own advantages.

Also do you mind sharing your finishing routines, eg. Sandpaper grits, primers, putty, paints, topcoat (and product brands)?

PLA is best for regular use as it requires a lower temperature, usually up to a 40 degree difference needed on both the hotend and bed for PETG and ABS, running a printer for dozens of hours you want that most of the time.

for finishing I use low grit sandpaper and work up to finer grit, then coat in primer/filler

any holes/gaps that need filling (like on the hulk) before any of that I use woodfill and sand)

sand, more coats of primer and sanding..

Paint with acrylics (usually airbrush but my airbrush was down when I did the hulk so I had to do it by hand)

#Phonepunk#

Banned

i don't have the space for it and there are already a half dozen other projects i would get into but don't have the space for either.

also i have a certain use in mind: printing LPs. making homemade LPs has long been a dream of mine and i've purchased some record lathes and tried various cutting methods on different material. tbh having LPs printed is a huge hassle, it is only economic when you are dealing in large quantities, there is a large upfront setup charge for plating, etc. being able to print out records one at a time would rule, but it would also require a really high resolution printer. i figure 3D printing tech is only going to get better and more user friendly and eventually i will be able to buy one in Target or whatever.

also i have a certain use in mind: printing LPs. making homemade LPs has long been a dream of mine and i've purchased some record lathes and tried various cutting methods on different material. tbh having LPs printed is a huge hassle, it is only economic when you are dealing in large quantities, there is a large upfront setup charge for plating, etc. being able to print out records one at a time would rule, but it would also require a really high resolution printer. i figure 3D printing tech is only going to get better and more user friendly and eventually i will be able to buy one in Target or whatever.

i'll absolutely get into it once the texture fidelity gets a bump

will be fun to develop and print all kinds of models

It has with SLA printing. It's down to 10s of microns in later height. BUT, SLA is pricey, messy and toxic due to the resins.

I hope we see a lot more development in this space in the coming years. I think prices for printers should come down more, because you have a $200 Ender 3 giving $1000-$2000 printers reasonable competition.

JCK75

Member

i'll absolutely get into it once the texture fidelity gets a bump

will be fun to develop and print all kinds of models

I print at 0.2mm layer height because it's fast and pretty good, they care capable of .05 easily, it takes much longer but produces nearly perfect results.

example of when I do this

I used the profile and tricks taught here

If I applied that layer height to a larger model the lines would be pretty much not existent... but would quadruple print time

Last edited:

Omega Supreme Holopsicon

Banned

Don't know shapeways has 100,000+$ k printers, can always order from them or one of their competitors and get state of the art multi material multi color prints. Even with complex gears or structure.

Better to put designs there for others to buy, and get my own printer later.

Besides what I want is an altered carbon style 3d printer to print artificial lifeforms and that's a way off.(as has already been shown complex cells are able to function even at extraordinarily low metabolic rates, this modification to human cells could allow them to be 3d printed into organs without need for the working vasculature to be functioning for waste nutrient exchange given extreme metabolic slowdown while awaiting starting of organ function after prints are done.)

Better to put designs there for others to buy, and get my own printer later.

Besides what I want is an altered carbon style 3d printer to print artificial lifeforms and that's a way off.(as has already been shown complex cells are able to function even at extraordinarily low metabolic rates, this modification to human cells could allow them to be 3d printed into organs without need for the working vasculature to be functioning for waste nutrient exchange given extreme metabolic slowdown while awaiting starting of organ function after prints are done.)

Last edited:

I rarely have a need for 3D printed items. I can see some use cases, like if you're into table-top gaming or have kids, so you can print them cheap toys. I've tossed around the idea of buying one, but I never really need anything. Most of the things I could print would be nice to haves, but not necessities. If I really, really need something, my dad has one and can print for me, but I've only asked him to print something for me once. To print anything of decent size, it requires a larger printer which, in turn, bumps up the price.

Also, it feels like the quality isn't there yet. Everything I've seen printed is obviously 3D printed and has that texture to it. It also seems like delicate pieces break more easily. I had my dad print some laptop camera covers for me and they've all broken, despite being very careful with their use.

I think it would be better for me to wait to see if any improvements are made in upcoming years than getting something right now. I do have a thingiverse account that I use to occasionally find stuff that I would like to have someday.

Also, it feels like the quality isn't there yet. Everything I've seen printed is obviously 3D printed and has that texture to it. It also seems like delicate pieces break more easily. I had my dad print some laptop camera covers for me and they've all broken, despite being very careful with their use.

I think it would be better for me to wait to see if any improvements are made in upcoming years than getting something right now. I do have a thingiverse account that I use to occasionally find stuff that I would like to have someday.

Omega Supreme Holopsicon

Banned

I rarely have a need for 3D printed items. I can see some use cases, like if you're into table-top gaming or have kids, so you can print them cheap toys. I've tossed around the idea of buying one, but I never really need anything. Most of the things I could print would be nice to haves, but not necessities. If I really, really need something, my dad has one and can print for me, but I've only asked him to print something for me once. To print anything of decent size, it requires a larger printer which, in turn, bumps up the price.

Also, it feels like the quality isn't there yet. Everything I've seen printed is obviously 3D printed and has that texture to it. It also seems like delicate pieces break more easily. I had my dad print some laptop camera covers for me and they've all broken, despite being very careful with their use.

I think it would be better for me to wait to see if any improvements are made in upcoming years than getting something right now. I do have a thingiverse account that I use to occasionally find stuff that I would like to have someday.

Omega Supreme Holopsicon

Banned

If you could miniaturize the latest disney like animatronics that would make some pretty worthy 3d prints with custom characters. I mean robotic miniaturization is getting to the point where very good mini lifelike androids may soon be possible. But barring that high quality 3d print statues seem almost as expensive as official merchandise statues and figurines.

lifa-cobex

Member

Need some help using Blender as these issues are diving me crazy.

So I started trying to follow this guy in an attempt to work out how blender works...

So far I've been OK copying him.

However all my parts are intersecting with one another which is obviously a pain if I want to print....

So i decided to join all the parts up into one big mesh (which too ages). However that's become a problem as I'm now having problems with loading into Meshmixer as it's coming up with a shit ton of errors and deleting good chunks of it.

Plus I can't seem to load it into my slicer without parts dissapearing.

Does anyone know how I can take each part and have them line up with each other so I can print them individually and then glue them all together??

So I started trying to follow this guy in an attempt to work out how blender works...

So far I've been OK copying him.

However all my parts are intersecting with one another which is obviously a pain if I want to print....

So i decided to join all the parts up into one big mesh (which too ages). However that's become a problem as I'm now having problems with loading into Meshmixer as it's coming up with a shit ton of errors and deleting good chunks of it.

Plus I can't seem to load it into my slicer without parts dissapearing.

Does anyone know how I can take each part and have them line up with each other so I can print them individually and then glue them all together??

Need some help using Blender as these issues are diving me crazy.

So I started trying to follow this guy in an attempt to work out how blender works...

So far I've been OK copying him.

However all my parts are intersecting with one another which is obviously a pain if I want to print....

So i decided to join all the parts up into one big mesh (which too ages). However that's become a problem as I'm now having problems with loading into Meshmixer as it's coming up with a shit ton of errors and deleting good chunks of it.

Plus I can't seem to load it into my slicer without parts dissapearing.

Does anyone know how I can take each part and have them line up with each other so I can print them individually and then glue them all together??

I'm not fully understanding your issue, but I can try to help.

I briefly looked at the video, it seems the model is made up of separate parts? In this case there are a few options:

- You can intersect the parts in Blender and use the Boolean difference modifier to cut out the large part from the small parts, so they have a perfect interface where they join. Conversely you can cut the small parts into the large part, whichever makes more sense. Then save all your parts separately and print them out (you can select each part and save selection). If your parts are not separate objects there is a way to make them separate objects, I believe you select their mesh in edit mode and then press P and then selection, this should bring out the selected mesh into its own object

- The other way is to use the union boolean modifier to brute force combine all the parts together (do this a pair at a time). This doesn't always work so you have to check your mesh (press Z to see all the edges). Sometimes it's because you try to union in a way that results in bad geometry

- If a part is too complex to print as one piece, you can use meshmixer to slice it up into separate pieces along Cartesian planes

Also this tutorial is not particularly good for learning blender. May I recommend some others?

You are probably far along to try this now:

Also, if you like character modeling, here is another one I like: (skin modifier is extremely valuable for simple characters)

More advanced character modeling here:

Blender (and mesh modeling in general) is challenging because it's very easy to generate bad geometry. This is a good video covering how to fix the common problems you may come across once you get around to sculpting (which hopefully you plan to, as it's quite fun and you can make things a lot more interesting):

Hope that helps.

sonomamashine

Member

Print me a 3D printer, i'm broke.

nikolino840

Member

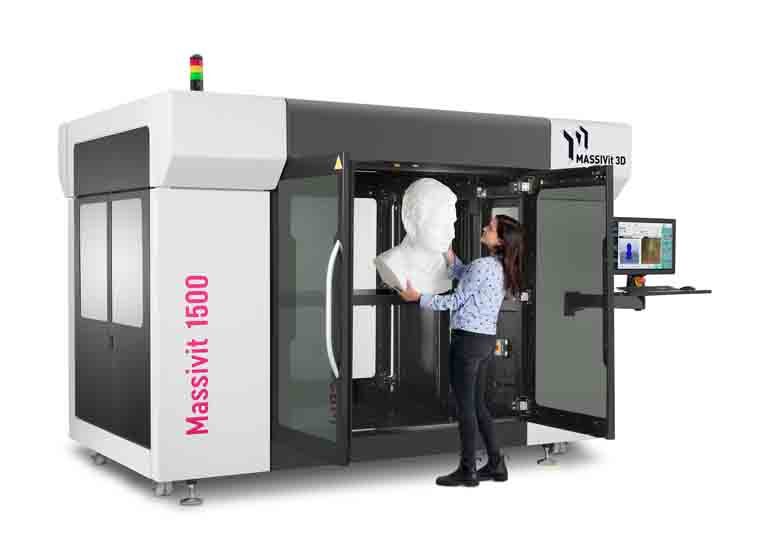

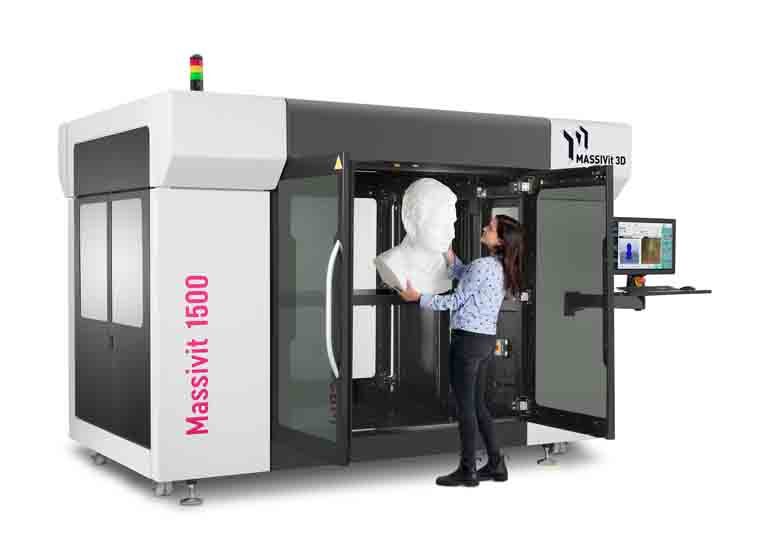

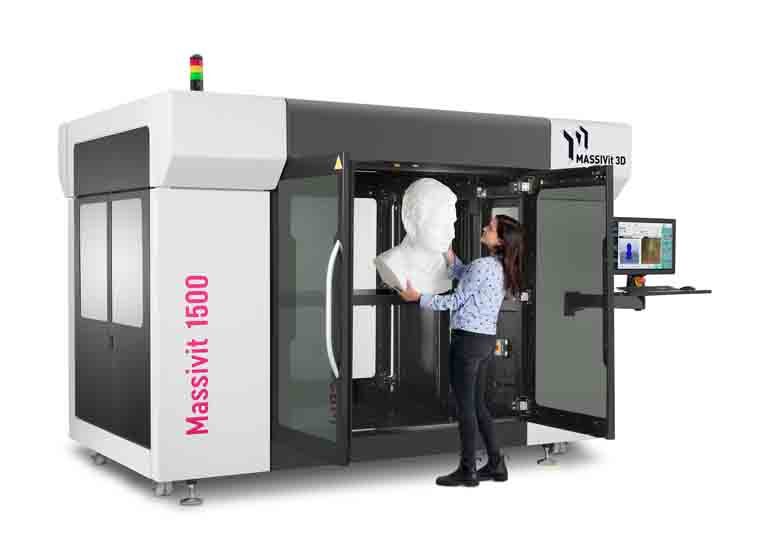

3d printers are too small..

Need something like this

Need something like this

Last edited:

3d printers are too small..

Need something like this

Did you mean like this:

lifa-cobex

Member

I'm not fully understanding your issue, but I can try to help.

I briefly looked at the video, it seems the model is made up of separate parts? In this case there are a few options:

- You can intersect the parts in Blender and use the Boolean difference modifier to cut out the large part from the small parts, so they have a perfect interface where they join. Conversely you can cut the small parts into the large part, whichever makes more sense. Then save all your parts separately and print them out (you can select each part and save selection). If your parts are not separate objects there is a way to make them separate objects, I believe you select their mesh in edit mode and then press P and then selection, this should bring out the selected mesh into its own object

- The other way is to use the union boolean modifier to brute force combine all the parts together (do this a pair at a time). This doesn't always work so you have to check your mesh (press Z to see all the edges). Sometimes it's because you try to union in a way that results in bad geometry

- If a part is too complex to print as one piece, you can use meshmixer to slice it up into separate pieces along Cartesian planes

Hope that helps.

This is defiantly what I need.

They guy in the vid made it all out of different parts but then towards the end, he glazed over how he fit them all together.

My issues is that Boolean doesn't always work for some reason. I've managed to do the front teeth successfully but the side parts aren't playing nice for some reason.

I think I have to just keep editing it in some way until it all fits.

I've loaded it into Meshmixer a few times and it comes up with a shit ton of errors. Resolving them ends up deleting loads of parts. So again I think my best bet is to print them off into pieces when I figure out how.

I may even start again from scratch but because I've put so much work into this, I'm hesitant

I'm defiantly gonna go through those videos at some point. Especially the one about with the Anvil.

Just wanna nail this project first before moving onto anything else.

However you've been a massive help.

Cheers for your time buddy.

This is defiantly what I need.

They guy in the vid made it all out of different parts but then towards the end, he glazed over how he fit them all together.

My issues is that Boolean doesn't always work for some reason. I've managed to do the front teeth successfully but the side parts aren't playing nice for some reason.

I think I have to just keep editing it in some way until it all fits.

I've loaded it into Meshmixer a few times and it comes up with a shit ton of errors. Resolving them ends up deleting loads of parts. So again I think my best bet is to print them off into pieces when I figure out how.

I may even start again from scratch but because I've put so much work into this, I'm hesitant

I'm defiantly gonna go through those videos at some point. Especially the one about with the Anvil.

Just wanna nail this project first before moving onto anything else.

However you've been a massive help.

Cheers for your time buddy.

One more thing I forgot to mention - you can often fix problems by using the 3d printing plugin and "make manifold". An online conversion service called Netfabb has a more powerful engine for doing this if Blender fails. This fixes bad geometry and often solves problems with Boolean operations.

Fnord

Member

Like others in the thread, I also have jumped into 3D printing (the helmet in my avatar was printed on my CR-10). I have a CR-10, a CR-10S Pro, and an Anycubic Photon SLA printer. Recently designed and printed a curing station for the Photon, just waiting for the UV LED light strip to arrive from Amazon to assemble it.

Fnord

Member

It depends on what plastic you print with.

PLA is strong/stiff but a bit brittle and not very heat resistant.

ABS/ASA is also strong but softer compared to PLA, it is heat resistant though and UV resistant as well. ASA is what I use for my phone stand in my car.

I basically use PETG for everything now. It has near the strength and heat resistance of ABS, but is as easy to print as PLA (and doesn't have the odor that ABS has).

I managed to pick up an Ender 3 for £120 about a year ago.

I've loved every moment of it. From the initial construction, to the on-going tweaks and modifications.

Here's a full size Wingman from Titanfall/Apex I printed.

Awesome.

Guiberu

Member

Awesome.

It is.

But it also took a whole lot of time, and filament.

I also bought the files for a fully customizable , articulated action figure. Will dig out pictures later.

The next big thing in home 3D printing IMO is going to be non-planar slicing. Most, if not all current home printers can use it. It's just a case of math, and someone writing a decent converter.

Guiberu

Member

ALSO.

Everyone should play with Tinkercad.

It's a free, browser based, simplified 3D editor. You can start from scratch and build with primitives, or import a model and edit from there.

Stupid simple, but incredibly powerful, and useful.

I've gone from idea, to rough model in Tinkercad, to having it physically in my hands, within an hour.

lifa-cobex

You could try importing your model into this, and cutting it in half with a primitive cube. Tinkercad deals with boolean operations rather well, from my experience.

lifa-cobex

You could try importing your model into this, and cutting it in half with a primitive cube. Tinkercad deals with boolean operations rather well, from my experience.

Everyone should play with Tinkercad.

It's a free, browser based, simplified 3D editor. You can start from scratch and build with primitives, or import a model and edit from there.

Stupid simple, but incredibly powerful, and useful.

I've gone from idea, to rough model in Tinkercad, to having it physically in my hands, within an hour.

Prison Mike

Banned

I work in 3d printing in the UK printing parts for f1 cars... Hamilton as well as nascar etc

J-Roderton

Member

I think my local library has a printer that can technically be rented out and used there. Dunno what I would print, though. I've seen some people do custom knife handles. Might do that with my next customized blade.

Ecto311

Member

Building a DIY Stream Deck (Mini Macro Keyboard) - Parts Not Included

I’ve been doing a little streaming on Twitch, and a lot of streamers I follow have something called an Elgato Stream Deck. The Stream Deck is a small device with 15 buttons, each of which Read more

www.partsnotincluded.com

www.partsnotincluded.com

Built this for my aspiring twitch streamer kid. Not sure what to do with the last button. It has an arduino inside and acts like a keyboard when plugged in.

The smart thing is it uses the F13 to F21 keys that map to OBS and can't be triggered by the normal keyboard in anyway that could be an accident. It was a fun build and cost maybe $15 for all the parts. The dumb paint job is my fuckery of painting into a bucket of water with spray paint and dipping the print. She likes the blue marble though.

Top row is Cherry MX Blue and Brown on bottom row. Nice to have a tactile sound so you don't have to stare at it directly to know if it's been pressed.